WELCOME OUR COMPANY

Turbo Machine Solution (TMS)

Turbo Machine Shop specializes in the precise production of custom design industrial equipment. TMS’s engineering departments design, develop, test, and manufacture custom industrial equipment to meet customer needs.

TMS has over 30 years of experience with equipment and components of all makes and models, including Absolute Equipment. These are some of the brands we service- Tetra Pak, Hoyer; Gram; Waukesha Cherry Burrell; SPX, APV/Crepaco, Alfa Laval, and Westfalia. TMS is well-experienced machine shop in Houston with satisfied clients from all over Texas.

We Have Experience

Industry Machine Shop In Houston. Experience as Machinist to serve in Texas and Nationwide

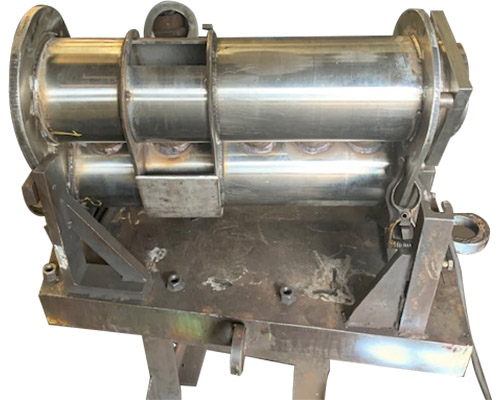

DASHERS & MUTATORS

Reconditioning Process

We begin the Dasher/Mutator repair process with a thorough inspection and evaluation of the current condition. We check pin alignment and thickness and inspect for stress fractures that may be found at the base of the pins. We perform an inspection of the bearing diameters and spline ends to determine if welding and machining are necessary.

Following repairs, we measure bulk heads, inner pins, and take TIR readings to ensure proper installation and performance. Solid units are subject to pressure testing up to 200 PSI to ensure all leaks and cracks have been completely sealed. After passing an inspection check-list; units are polished and shipped in our sturdy wooden crates.

TMS, Housto Machine Shop, has the capability to weld and machine all units. Severely worn surfaces can be plated to extend the working life.

Dashers and Mutators insert inside the cylinders; serving to constantly agitate product, as well as the axis of rotation for scraper blades. Dashers & Mutator blade shafts are necessary for mixing and churning product into a specific consistency. They come in many sizes and shapes; which are determined by their application. Most dashers have pins attached to their outside casing which serve to hold long blades. As the dasher spins, the blades scrape the product from the inner surface of the Heat Exchange Cylinder

Scraped Surface Heat Exchanger

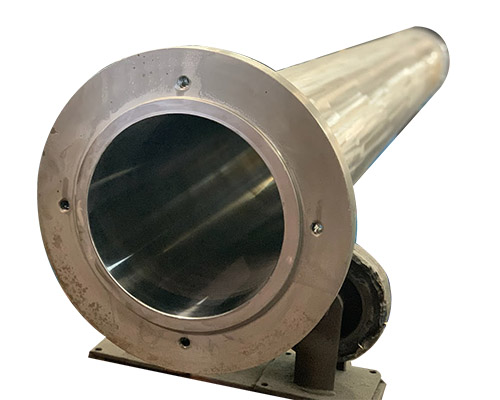

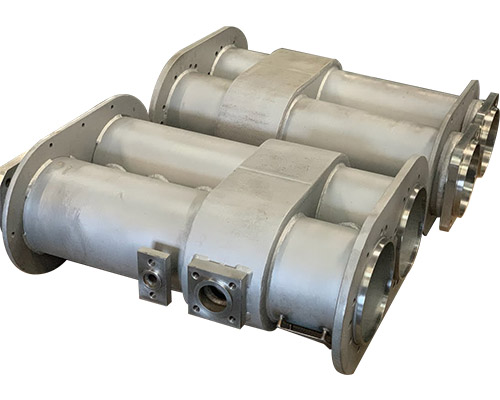

CYLINDERS, BARRELS & TUBES

No matter the material- Nickel, Stainless Steel, Copper, etc.- we know heat exchangers inside and out, better than anyone in the industry. Whether your application is hot or cold we’ve seen it, we’ve fixed it, we know it. Reach us today when you are looking for experienced Machine Shop in Houston or turbo machining company in Houston.

RECONDITIONING SERVICES

TMS prides itself on the ability to recondition units with the fastest turnaround in the industry. Cylinders, Barrels & Tubes can typically be reconditioned and re-chromed within 10 days for a fraction of the cost of a new unit. Most other damaged parts can typically be repaired in 14 days or less.

EXCHANGE SERVICES

TMS carries the world’s largest inventory of hard-chromed cylinders for exchange or purchase. In addition to our vast supply of cylinders, we stock many other parts and components in our inventory for exchange. Ingredient/Fruit Feeders, Pumps, Dashers, Inner Beaters and Whipper Cages are reconditioned per manufacturer’s specifications, ready to swap out with units in need of repair.

SPARE PARTS

TMS manufactures Bushings, Blades, Pump Shafts & Drive Shafts, Beater Bars & Winged Beaters, Homogenizer Pistons & Cylinder Sleeves. TMS ‘s spare parts can be manufactured per factory specification OR per specifically requested specification.

PURCHASING RECONDITIONED UNITS

Whether updating equipment, expanding facilities, purchasing spare units or replacing out-of-spec components, TMS is stocked with reconditioned units. All units are reconditioned and hard-chromed per manufacturer’s specifications; ready for installation and carry the same warranty as OEM equipment. Quotes are available upon request.

Need discussion, please call us at (713) 645 7000