Centrifuges are vital to industrial processes in oil & gas, chemical production, and food processing facilities across Houston, Pearland, Texas City, and Pasadena. These machines play a critical role in separating solids from liquids, purifying products, and maintaining operational efficiency. However, like any complex machinery, centrifuges are prone to wear and tear. When issues occur, they can cause costly downtime and disrupt production.

That’s where TMS Centrifuge Repair Services come in. Our team specializes in diagnosing, repairing, and maintaining centrifuge systems to ensure they operate at peak efficiency. In this blog, we’ll cover common centrifuge problems, the importance of professional repairs, our proven process, and why Texas industries trust TMS.

Table of Contents

- Why Centrifuge Maintenance Matters

- Common Centrifuge Problems in Industrial Settings

- The Benefits of Professional Centrifuge Repair

- TMS Centrifuge Repair Process

- Preventive Maintenance for Long-Term Performance

- Industries We Serve in Houston, Pearland, Texas City & Pasadena

- Why Local Businesses Trust TMS

- Final Thoughts

- Call to Action

1. Why Centrifuge Maintenance Matters

Centrifuges work under high stress and constant use, which makes them prone to breakdowns if not properly maintained. Even minor imbalances can create vibration issues that damage bearings and internal parts. Poor lubrication can lead to overheating, while contamination may cause premature wear. Without timely centrifuge repair Houston services, these issues can escalate, leading to production losses and expensive equipment replacements. Routine servicing not only improves efficiency but also extends the overall life of the machine.

2. Common Centrifuge Problems in Industrial Settings

Industrial centrifuge systems face several recurring issues that can disrupt operations if left unresolved. One of the most common problems is imbalance, which occurs when loads are uneven or parts are worn down. This imbalance creates excessive vibration that can damage internal components and reduce efficiency. Another frequent challenge is contamination—the buildup of dirt, oil, or product residue inside the system. Contamination not only accelerates wear but also lowers separation performance.

Bearing failure is another issue that industries often face. It usually results from poor lubrication or prolonged vibration, both of which can compromise machine reliability. Over time, centrifuge seals also wear down, leading to leaks and the intrusion of contaminants. In some cases, operators notice overheating, which may stem from excessive friction, blocked cooling channels, or a failure in lubricant quality.

When these problems are not addressed quickly, they can lead to costly downtime and production losses. Timely intervention through professional centrifuge separator repair Houston services ensures smooth operations and prevents minor issues from turning into major failures.

3. The Benefits of Professional Centrifuge Repair

Working with an experienced repair provider like TMS offers significant benefits:

- Reduced Downtime – Local repairs ensure faster turnaround compared to replacements.

- Cost Savings – Repairs are far less expensive than purchasing new centrifuge systems.

- Extended Lifespan – Professional servicing restores equipment to near-new condition.

- Improved Safety – Correcting imbalances and mechanical issues reduces workplace risks.

- Higher Efficiency – Well-maintained centrifuges operate at peak performance.

For Texas industries, the combination of speed, quality, and reliability makes centrifuge repair services a smart investment.

4. TMS Centrifuge Repair Process

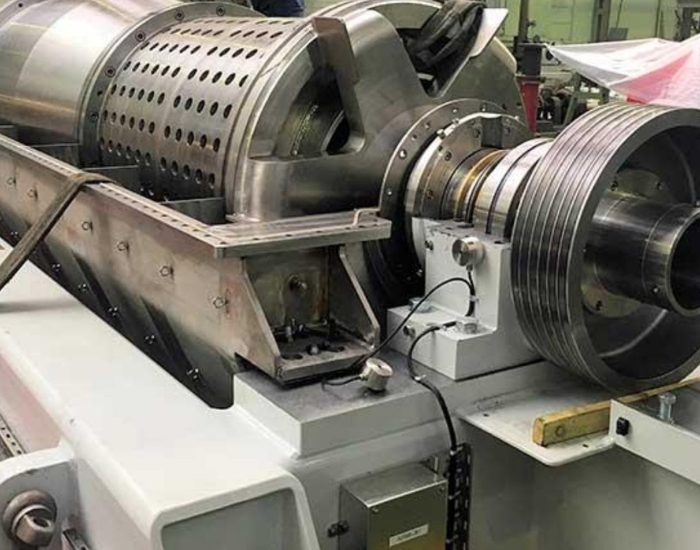

At TMS, we use a proven process to restore centrifuge systems with precision.

Our repair approach includes:

- Inspection & Diagnostics – Identifying the root causes of imbalance, wear, or failure.

- Component Disassembly – Carefully dismantling the centrifuge for detailed evaluation.

- Precision Machining & Replacement – Restoring worn parts or replacing them with quality components.

- Balancing & Reassembly – Ensuring the centrifuge operates smoothly without vibration.

- Testing & Quality Assurance – Running performance tests before delivery.

This step-by-step approach ensures every centrifuge repair Houston TX project meets strict performance and safety standards.

5. Preventive Maintenance for Long-Term Performance

Proactive maintenance is the best way to keep centrifuge systems reliable. Businesses should schedule routine inspections to catch early warning signs of imbalance, leaks, or bearing wear. Monitoring vibration levels helps identify misalignment before it worsens, while checking seals and lubricants ensures the system operates efficiently. TMS offers tailored preventive maintenance programs that save money by reducing the risk of major breakdowns. Regular servicing not only minimizes costly downtime but also helps companies plan maintenance around production schedules, keeping operations efficient and uninterrupted.

6. Industries We Serve in Houston, Pearland, Texas City & Pasadena

At TMS, our centrifuge repair services are designed to support a wide range of industries across Houston and surrounding areas. In the oil and gas sector, centrifuges play a crucial role in refining, drilling, and processing, where efficiency is key to meeting production demands. Our expertise also extends to chemical processing plants, where precise separation is critical to maintaining safety and product quality.

We also serve the food processing industry, where centrifuges are vital to ensuring sanitary, large-scale production. Any downtime in this sector can lead to significant losses, making rapid repair services essential. Beyond that, we assist manufacturing facilities, where centrifuges are used in material separation and quality control processes.

By focusing on Houston, Pearland, Pasadena, and Texas City, TMS provides localized solutions that combine quick response times with a personal touch. Unlike larger national providers, we deliver services tailored to the unique demands of Texas industries, helping businesses minimize downtime and maximize reliability.

7. Why Local Businesses Trust TMS

TMS has built a strong reputation in Texas by consistently delivering quality centrifuge repairs. Our local expertise allows us to respond quickly to the needs of industries in Houston, Pearland, Pasadena, and Texas City. We pride ourselves on fast turnaround times, ensuring equipment returns to service with minimal disruption. With advanced machining capabilities, skilled technicians, and a customer-first approach, we provide reliable solutions that clients can trust. Over the years, our proven track record has made us a go-to provider for centrifuge separator repair Houston businesses.

8. Final Thoughts

Centrifuge systems are essential for many industries in Texas, but even minor problems can cause major operational setbacks. With expert centrifuge repair and field services from TMS, businesses can avoid costly downtime, extend the life of their equipment, and maintain peak performance. Whether it’s routine servicing, preventive maintenance, or emergency repairs, TMS provides dependable solutions tailored to your industry.

9. Call to Action

Don’t let centrifuge failures interrupt your operations. Partner with TMS Turbo Machining Inc. for reliable repairs, maintenance, and field support across Houston, Pearland, Pasadena, and Texas City.

Schedule a free consultation today and discover why Texas industries trust TMS for their most critical machinery.