For industries in Houston, Pearland, Texas City, and Pasadena, turbo machines are the backbone of productivity. When these critical machines begin to wear, companies face a tough decision: should they invest in turbo reconditioning or opt for full replacement?

This decision impacts cost, downtime, and long-term efficiency. In this guide, we’ll break down the key differences, examine the benefits of each approach, and help you make an informed choice tailored to your operations.

Table of Contents

- What Turbo Reconditioning Really Means

- How to Recognize Turbo Wear and Tear

- Advantages of Reconditioning Your Turbo

- When Replacement Is the Better Option

- Cost vs. Efficiency: Comparing Options

- Why Local Houston Services Make a Difference

- Industries That Rely on Turbo Efficiency

- TMS’s Approach to Restoring Turbo Performance

- Choosing the Right Solution for Your Operation

- Final Thoughts

- Call to action

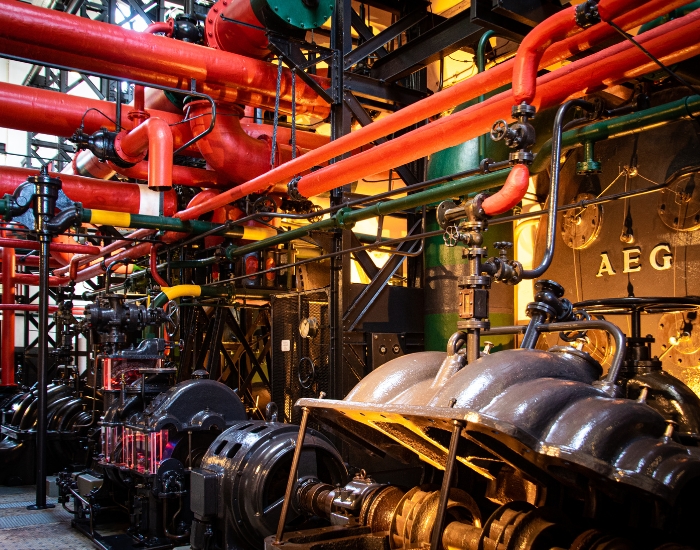

1. What Turbo Reconditioning Really Means

Turbo reconditioning is more than a standard repair; it’s a precision process designed to restore worn turbo machines to near-new performance. Unlike a full replacement, reconditioning involves complete disassembly and detailed inspection of the turbo unit, repairing or re-machining worn or damaged components, and balancing rotors and other moving parts with exact precision. After reassembly, the machine undergoes rigorous performance testing to ensure it operates efficiently. The primary goal of turbo reconditioning is to extend the equipment’s life, improve operational efficiency, and avoid the higher costs and long lead times associated with purchasing a new unit.

2. How to Recognize Turbo Wear and Tear

Recognizing when a turbo needs attention can save businesses from costly downtime. Common warning signs include noticeable declines in performance or slower output, excessive vibration or unusual noises, overheating or repeated shutdowns, oil leaks or contamination, and visible corrosion or damaged parts. By detecting these issues early, businesses can make an informed choice between reconditioning or replacement, preventing major operational disruptions and protecting productivity.

3. Advantages of Reconditioning Your Turbo

Reconditioning offers significant benefits for Houston-area industries:

- Lower Operational Costs – Reconditioning is much less expensive than purchasing a new unit.

- Reduced Downtime – Local services allow rapid turnaround, keeping operations on track.

- Sustainable Solution – Extends equipment life while minimizing waste.

- Restored Performance – A properly reconditioned turbo can perform like new.

- Local Support – Houston-based providers respond quickly to urgent needs.

For businesses seeking fast, efficient, and cost-conscious solutions, reconditioning is often the smartest choice.

4. When Replacement Is the Better Option

While reconditioning is often the most cost-effective solution, replacement may be necessary in certain circumstances. For example, if the turbo has extensive damage where core components cannot be repaired, or if the equipment is obsolete and incompatible with modern systems, replacement becomes the practical choice. New units also come with full manufacturer warranties and may offer opportunities for upgrades, such as higher efficiency, improved energy consumption, or advanced technology integration. Though replacement typically involves higher costs, it provides long-term reliability for machines that are severely worn or outdated.

5. Cost vs. Efficiency: Comparing Options

Financial and operational factors should guide the decision:

- Reconditioning generally saves 40–60% compared to new units.

- Replacement may involve longer lead times, potentially increasing downtime.

- Reconditioned units restore efficiency and extend machine life at a fraction of the cost.

- Replacement provides peace of mind for severely damaged or obsolete equipment.

Weighing short-term costs against long-term operational benefits is essential for Houston businesses.

6. Why Local Houston Services Make a Difference

Partnering with a local Houston-based turbo service provider offers benefits beyond just cost savings. Rapid service ensures on-site teams can arrive quickly to minimize production interruptions. Local experts also have industry-specific knowledge, understanding the unique operational requirements of oil, gas, manufacturing, and food processing facilities. Customized solutions are tailored to your equipment and workflow, while ongoing support, including preventive maintenance and follow-up services, reduces the likelihood of future failures. By choosing local expertise, businesses in Houston, Pearland, Pasadena, and Texas City gain faster, more responsive service and reliable results.

7. Industries That Rely on Turbo Efficiency

Turbo machines are critical across multiple industries. In the oil and gas sector, they keep turbines, compressors, and pumps running efficiently in refineries and plants. Manufacturing facilities depend on turbos to maintain smooth production lines and minimize downtime. Food processing operations rely on turbo-driven mixers, grinders, and pumps to ensure hygienic and continuous operations, while chemical plants use turbo machines for critical separation, mixing, and processing tasks. High-performing turbo equipment directly impacts productivity, operational safety, and overall efficiency across these sectors.

8. TMS’s Approach to Restoring Turbo Performance

At TMS, turbo reconditioning and repair services are delivered with precision and professionalism. The process begins with a comprehensive inspection to detect worn, damaged, or imbalanced parts. Next, components are rebuilt through re-machining, replacement, and precise balancing to restore optimal performance. After reassembly, machines are rigorously tested to ensure they operate at peak efficiency, with performance verification confirming vibration-free operation. Additionally, TMS provides preventive maintenance guidance, offering a roadmap to extend equipment life and reduce the risk of future failures. This structured methodology ensures Houston-area businesses receive high-performance, reliable turbo solutions.

9. Choosing the Right Solution for Your Operation

Deciding between reconditioning and replacement requires evaluating several factors, including the extent of wear or damage, the age and model of the turbo, budget constraints, tolerance for downtime, and long-term operational goals. For most industrial businesses in Houston, Pearland, Pasadena, and Texas City, reconditioning offers a cost-effective, rapid, and sustainable solution that restores performance without the high cost of a new unit. Replacement may be more appropriate for severely damaged or outdated machines. Consulting with a trusted local provider like TMS ensures businesses make the right choice, maximizing efficiency and minimizing operational disruptions.

10. Final Thoughts

Choosing between turbo reconditioning and replacement is a critical decision that can significantly impact your business’s efficiency, costs, and uptime. For most Houston-area industries, reconditioning offers a fast, cost-effective, and sustainable solution that restores performance while minimizing downtime. Replacement may be necessary for severely damaged or obsolete equipment, but it typically comes with higher costs and longer lead times. By working with a trusted local provider like TMS, businesses in Houston, Pearland, Pasadena, and Texas City can make informed decisions, ensure reliable turbo performance, and keep operations running smoothly for the long term.

11. Call to Action

Keep your turbo machines running at peak performance without unnecessary downtime or expense. Contact TMS Turbo Machining Inc. today for expert guidance, fast service, and reliable solutions in Houston, Pearland, Pasadena, and Texas City.

Schedule a consultation now and restore your critical machinery efficiently and safely.